Multifunctional block machine

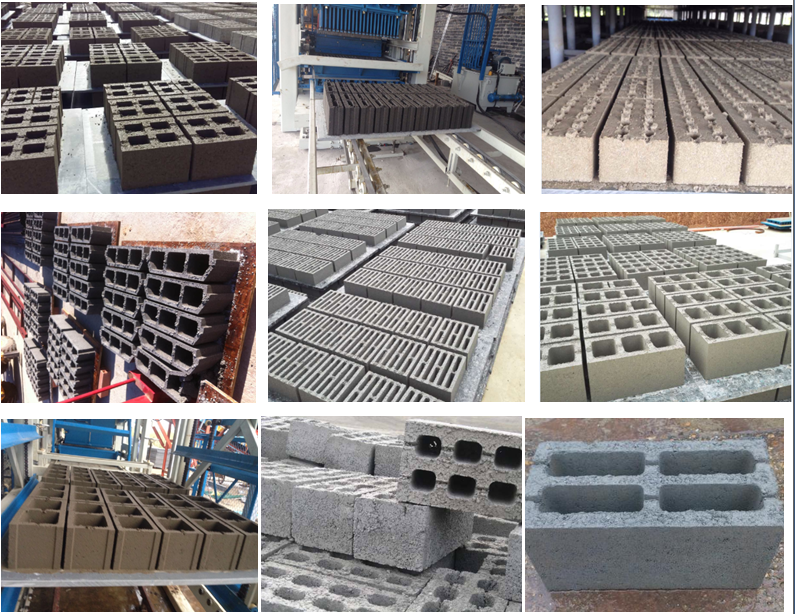

Block machinery is a building material machinery that uses slag, slag, fly ash, stone powder, sand, stones, cement, etc. as the main raw materials to press blocks or bricks through a hydraulic system at high pressure.

The cement bricks or hollow blocks produced by the block machinery do not need to be sintered and can be shipped out in a short time. The cement bricks or hollow blocks produced by the block machine effectively protect the precious land resources of our country. Realize the reuse of resources, such as slag, slag, construction waste, etc. that everyone considers to be garbage, which can be converted into non-burning bricks through the brick making machine equipment, thus realizing the recycling of resources, and the block machinery is less investment. , With quick results, is currently a popular industry for many investors to invest in.

The overall structure of the machine is compact, the equipment is reasonable, and the rotating parts adopt mechanized devices, which are accurate and reliable. Reduce labor intensity and improve production efficiency. Pressing up and down, directional vibration, frequency conversion braking, to achieve high-density, high-strength molding effect. One machine for multiple purposes, with different molds to produce

The multifunctional block forming machine produces block products of different shapes and specifications. The mechanical structure of each part is easy to observe, simple to operate, convenient to maintain, and not prone to failure to ensure normal production operation.

(1) The block machine is a fixed, platform-vibrated, mechanical demoulding. The model is advanced and reasonable in design and has a wide range of applications. It adopts a reducer and brake magnet to surround the demoulding.

(2) Adopting 4 uprights, the positioning is accurate, the mould is balanced and stable, the density of the block is improved, the block has small burrs and good appearance.

(3) Die replacement is convenient, simple and easy to maintain.

The above description is the large and medium-sized automatic block forming machine equipment, and there are also small block forming machines. Generally speaking, this equipment is defined according to the size of the daily output. At present, the daily production of standard bricks is about 10,000. , Are called small, because the overall design of this equipment is relatively simple, so it is more convenient for users to operate. Large block forming machines generally use hydraulic and vibration forming, while small block forming machines generally use vibration forming, but the quality of products produced by small equipment is not inferior to that of large equipment.

The overall structure of the machine is compact, the equipment is reasonable, and the rotating parts adopt mechanized devices, which are accurate and reliable. Reduce labor intensity and improve production efficiency. Pressing up and down, directional vibration, frequency conversion braking, to achieve high-density, high-strength molding effect. One machine with multiple functions, with different molds, can produce block products of different shapes and specifications. The mechanical structure of each part is easy to observe, simple to operate, convenient to maintain, and not prone to failure to ensure normal production operation.

The overall design of this equipment is relatively simple, so it is more convenient for users to operate. Large block forming machines generally use hydraulic and vibration forming, while small block forming machines generally use vibration forming, but the quality of products produced by small equipment is not inferior to that of large equipment.

Compared with advanced foreign production equipment, the main gap between Chinese block production equipment and foreign advanced production equipment is that the reliability is not as good as that of foreign equipment. The electrical components, hydraulic components and mechanical accessories used in foreign block production equipment are all products of world-renowned companies, so the equipment failure rate Lower, more reliable to use. From the perspective of the use of China's block production equipment, the faults are mostly in electrical, hydraulic and mechanical accessories, while the electrical components, hydraulic components and mechanical accessories used by various equipment manufacturers are relatively complex, and the quality is relatively poor, especially electrical and hydraulic There is still a big gap between the quality of components and foreign countries. Therefore, the development of electrical, hydraulic and mechanical accessories suitable for block production equipment to improve the reliability of the equipment is also very important for the block production industry. In order to improve the reliability of China's block production equipment, in addition to strengthening the development of domestic accessories, foreign high-quality electrical and hydraulic components can also be used to improve the reliability of domestic equipment, so that China's block production equipment is also available in the international market. Certain competitiveness.

1. Compared with the traditional clay brick machine, the block forming machine can choose industrial waste slag as raw materials: coal ash, coal gangue, slag, smelting slag and various tailings slag as the main raw materials, which is more environmentally friendly, more energy-saving, and waste recycling.

2. The block forming machine adopts three bars to press up and down to form once, and it can be stacked immediately after forming, without a brick supporting board. It is the latest model among domestic block bricks.

3. The standard brick produced by the block forming machine has low cost and high profit. Taking all necessary costs into account, each standard brick costs 9 cents, which is 2-3 times the market price.

4. The block forming machine body is made of high-precision, high-strength castings and special welding technology and materials, with good rigidity, vibration resistance and long life.

5. The block forming machine adopts table mold clamping vibration hydraulic pressure forming, adopts reciprocating guide feeding device, short forming cycle, high production efficiency, high block quality, high density and strength, and precise size.

6. The block forming machine adopts mechanical, electrical, and hydraulic integration technology to make every cycle of the equipment operation consistent, so the forming output is high and the stability is high, and the rejection rate is low.

7. The block forming machine is multi-purpose. By changing the mold, it can produce different specifications of porous bricks, hollow blocks, curbs, pavement bricks, grass tree bricks, lattice bricks and other cement products.

8. Programs can be programmed according to production needs to realize manual, semi-automatic, fully automatic and other actions.